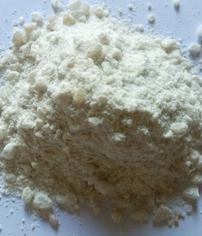

Ramming Mass

MXR India produces ramming mass using good quality quartzite having very high purity Sio2 around 98.5% to 92.5%. The produces are free from impurities and contains exact composition for yeilding tempature of around 1700 - 1750°C . High purity silica yields more lining life. It also results in considerable uniformity in physical properties.

Granulometric composition of commercial silica ramming mass

5mm-1mm : 33%

1mm-.20mm : 30%.

0.02mm-0.60mm : 17%

0.06mm and below: 20%

** Grain size can also be set as per customers requriement of Grain Size uto 7MM

Grade of Ramming Mass for different Induction Furnace.

Our Ramming Mass product is manufactured in perfect combination to provide high heat cycles and allowing clients save money on repeated lining of furnace.

Grade - I

PREMIX RAMMING MASS : Our Super grade is Premix Ramming Mass With Boric Acid precentage from 1.2% to 1.8%.

ACIDIC RAMMING MASS POST MIX : Super grade of acidic ramming mass without Boric Acid.

Material Specifications for Grade-I Ramming Mass

Grains - High Grade Quartzite Grains with high Sio2 content

High Grade of Quartz powder in perfect Mesh size for better setting

Technical Data Analysis for Grade-I Ramming Mass

High content of SiO2 from 98.4% to 99.1%

Low Fe content upto 0.02-0.04%%

Al2O3: 0.1-0.3%

Na2O: Absent

K2O: 0.005%

Lime (CaO): Less then 0.O1% or absent

MgO: Less then 0.01% or absent

Bulk Density :01.525 gm per CC

Moisture : 0.00 at 110 degree Centigrade

LOI: Less then 0.5%

Grade - II Acidic Ramming Mass and Nali Top Ramming Mass

We are manufacturing grade II ramming mass for wrought Iron, Iron Scrap, Continous casting. The material is manufactured with good grade of quartzite material giving upto 18 heat cycles. Similarly we are also manufactruing Nali Top ramming mass for lining. We have good production capacity to meet regular demand of clients.

High content of SiO2 from 97% to 99%

LOI: Less then 0.5%

Low Fe content upto 0.02-0.04%%

Al2O3: Trace

Soda & Potash: Trace or NIL

Lime (CaO): Less then 0.1%